In today’s fast-paced manufacturing environment, the push for efficiency is constant. From production lines to the supply chain, companies are always looking for ways to streamline operations, reduce waste, and increase profitability. As someone with experience or at least a vested interest in the manufacturing industry, you know the complexity of these challenges. But there’s a new tool in the kit that’s changing the game: automation.

Automation is no longer just about replacing human labor. It’s about solving complex problems and improving operations in a way that benefits everyone involved. In this blog, we’ll explore how automation can help solve complex manufacturing problems without generating waste—and how you can leverage this technology to drive meaningful improvements in your own processes.

Understanding the Complexity

Manufacturing problems often stem from a combination of factors: human error, inefficiencies, resource mismanagement, and poor communication. The complexity lies not just in pinpointing where the problem lies but in finding solutions that address the issue without causing further complications.

For example, a production line might run at suboptimal speeds due to unoptimized equipment. A quick fix might be to just push the equipment harder, but that could lead to more breakdowns, or worse, safety issues. Similarly, trying to cut costs by reducing quality could backfire, resulting in products that don’t meet standards and lead to returns or recalls. The key is finding solutions that address the root causes of inefficiencies without creating additional waste, be it time, materials, or human resources.

The Role of Automation in Solving Complex Problems

Here’s where automation comes in. By integrating automated systems into your manufacturing processes, you can approach problems in a more systematic, data-driven way. Automation technology can help reduce waste, improve consistency, and optimize operations in several key areas.

1. Reducing Overproduction and Material Waste

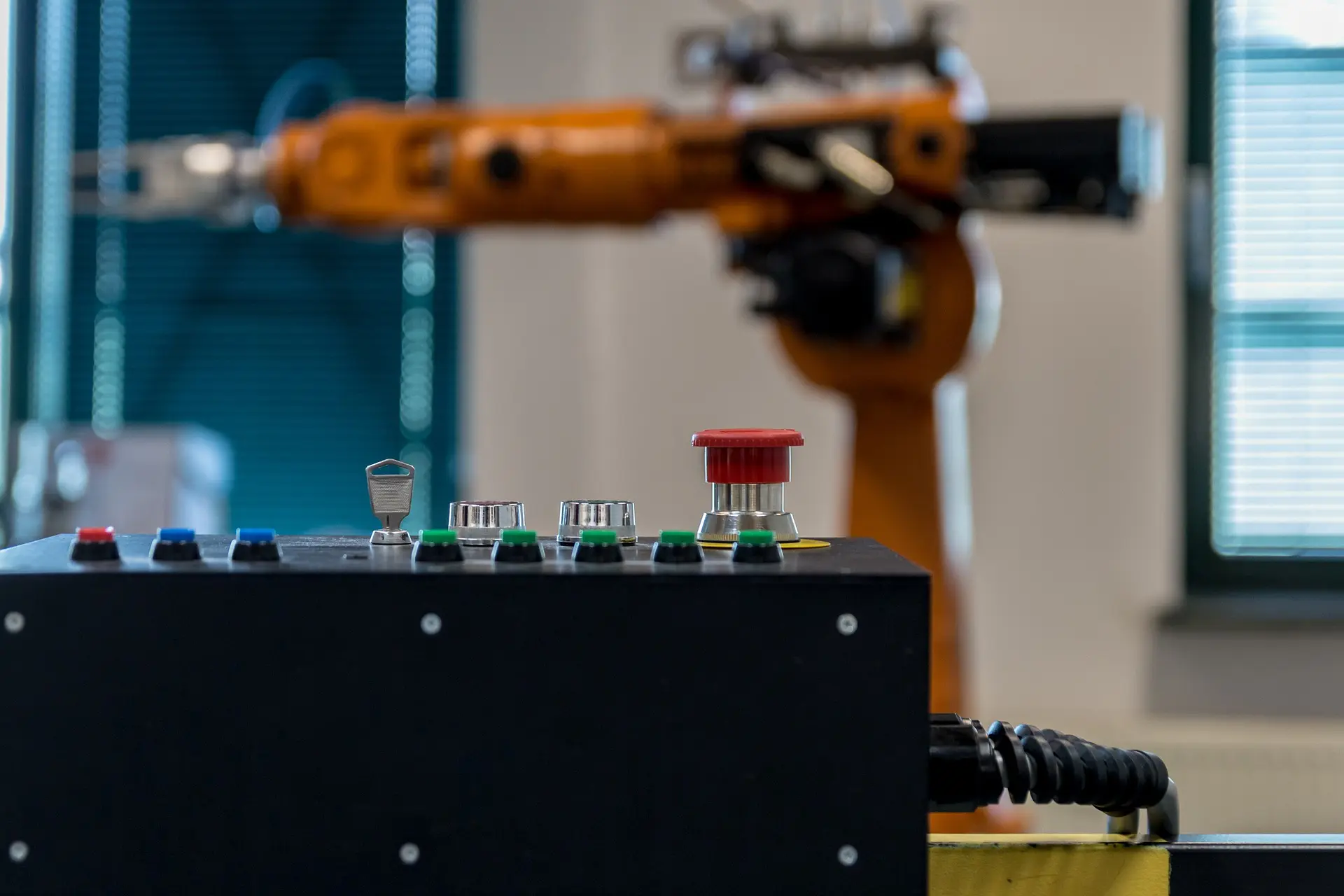

One of the most common types of waste in manufacturing is overproduction. Producing more than necessary not only wastes materials but also increases storage costs and complicates logistics. With automation tools like advanced scheduling software, robotic arms, and smart conveyors, you can better match production rates to actual demand. These systems can adjust production speeds based on real-time data, ensuring you’re never making more than what’s required and reducing unnecessary waste.

2. Improving Quality Control

Automation plays a huge role in enhancing product quality. With AI-driven inspection systems and automated testing, you can detect defects before they make it to the final stages of production. This reduces scrap and rework, which saves time, materials, and costs. Machines are also less prone to human error, so consistency in production quality improves.

For example, machine vision systems can spot even the slightest inconsistencies in products, while automated sorting systems can direct flawed items off the production line before they cause problems downstream.

3. Optimizing Equipment Utilization

Another significant source of waste in manufacturing is equipment downtime. A machine that’s frequently breaking down or running inefficiently can disrupt production and result in missed deadlines. Predictive maintenance, driven by automation and IoT sensors, can help here. By continuously monitoring equipment conditions and analyzing data for potential failure points, predictive maintenance systems can identify issues before they become costly problems. This not only helps in reducing downtime but also extends the life of your equipment, minimizing the need for expensive repairs and replacements.

4. Streamlining Workflow and Communication

Communication breakdowns and poor workflow are common in complex manufacturing environments. With automation, these issues can be mitigated. Real-time communication between different machines and workstations ensures that all parts of the production process are synchronized. Automated work scheduling and task management tools make it easier for teams to stay on the same page, reducing bottlenecks and delays.

Automation also helps manage inventory more efficiently. Smart systems can track stock levels, forecast demand, and ensure that materials are ordered and delivered just in time, minimizing the risk of overstocking or stockouts.

5. Sustainability and Environmental Benefits

Waste isn’t just about materials—it also involves energy consumption, emissions, and the environmental impact of manufacturing processes. Automation can help companies reduce their carbon footprint by optimizing energy use. Systems can adjust energy consumption based on production needs, ensuring that machines aren’t running unnecessarily, leading to lower energy bills and fewer emissions.

Additionally, automated systems can help with recycling and reusing materials more effectively. By ensuring that every part of the manufacturing process is optimized, automation helps reduce waste that ends up in landfills, aligning your company with sustainability goals while still maintaining a competitive edge.

Getting Started with Automation

If you’re looking to incorporate automation into your manufacturing processes, the first step is identifying which areas can benefit most. Start by analyzing your workflows and pinpointing the biggest pain points—whether it’s quality control, material waste, or equipment downtime. Then, evaluate which automated solutions can address these issues most effectively.

It’s important to note that implementing automation isn’t a one-size-fits-all solution. Every facility and process is different, and adopting automation requires careful planning, training, and potentially some upfront investment. But the long-term payoff is undeniable. By eliminating waste, increasing efficiency, and improving product quality, automation pays for itself over time.

Final Thoughts

In the automation world, solving complex manufacturing problems without waste isn’t just a lofty ideal; it’s entirely achievable. Automation isn’t just about replacing workers with machines; it’s about using advanced technologies to optimize every part of the production process. By reducing overproduction, improving quality control, and enhancing equipment utilization, automation helps manufacturers solve problems efficiently and sustainably.

In an industry as competitive and fast-paced as manufacturing, embracing these technological advancements is not just a smart move—it’s essential for staying ahead of the curve. So, if you haven’t already, it’s time to explore how automation can help you solve your toughest problems without generating waste. You’ll be glad you did.